How many times have you used a container to keep some food leftovers or something edible you’ve bought? What’s more, you’ve surely used some plastic items to keep some other house stuff. If you think about it, homes are full of plastic items. And a lot of houseware is made of this material.

In a broad sense, houseware refers to any item that outfits a home. So, it includes an array of objects that may be essential or decorative. The purchase of houseware is a non-stopping process for every people with a home and new appliances, items, and equipment are introduced constantly to the market.

From pots and pans, napkins, and washcloths to towels, plastic containers, or bedsheets, the diversity of houseware is just huge as it comes in so many different materials, sizes, colors, designs, and, well, of course, prices.

Leaving decorative and luxurious stuff apart, most homes in the world share a very common type of houseware: flatware, drinkware, cooking utensils, and every type of food storage containers. All of these are massively made through plastic design and manufacturing.

So, sure, these products are very successful just because they’re essential. And that’s why they’re a sure investment for any plastic company. These are very versatile items, they can be produced in many sizes and colors, so their design is suitable for customizing. Keep reading to find out the importance within the plastic industry and how design affects manufacturing for plastic products.

Plastic design and manufacturing: the data

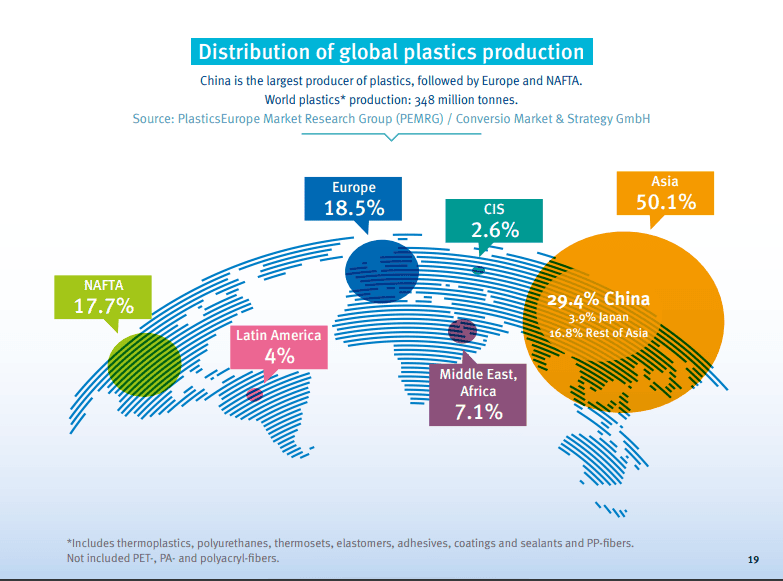

As we know, the plastic industry is a huge industry all over the world. Plastic production reached almost 350 million tonnes in 2017 [1]. Around 29% of that production comes from China, which had a turnover of little more than 300 billion USD. The next two producers are Europe (18.5%) and North America (17.7%) [1][2].

Around 1.5 million people in Europe are employed in the plastic industry, with around 60,000 companies, manufacturing, and suppliers included in the field, and about 395 billion USD of revenues in 2017 [1].

As for the United States, the plastic industry is the third biggest manufacturing industry of that country and in 2017 it employed about 1.8 million people, including both the manufacturing and the supplier sectors [3].

The U.S. plastic industry reported 432.3 billion USD in shipments in 2017, an annual increase of 6.9% [3]

Mexican market doesn’t get behind. As manufacturing companies expand in this country, Mexico’s plastic industry was the 10th largest producer in the world by 2016 with a market value of around 33 billion USD [4].

Mexico and the U.S. hold a privileged trading dynamic due to their geographical position. The former imported $15.8 billion in U.S. plastics just in 2015 [4], at a time when more U.S. companies have found in their southern neighbor a fertile land to establish their manufacturing plants.

As we look at these global dynamics, it’s not bold to state that U.S. companies have a great advantage by having close many Mexican manufacturing companies since costs of production and transportation are lower and favored by trade agreements between both nations.

Do you want to know more about the benefits of manufacturing in Mexico?

Read this article and find why companies are deciding to grow in this country.

Then, an important part of the plastic industry manufactures different types of houseware, including water bottles, lunch boxes, mugs, plastic cups, kitchenware, cooking utensils, items used daily around the world, and sometimes even made to be promotional products.

Houseware: plastic design and manufacturing

As flatware and drinkware come in thousands of different presentations and are widely used items all over the world, this offers a couple of advantages in the plastic industry: first, they will be easy-to-sell merchandise and secondly, they’re easily customizable.

Whether you want these items to be a regular product, part of your catalog, or whether they are part of a larger marketing strategy which includes promotional products, plastic design and manufacturing will be key to achieve the object you’re thinking of.

In order to produce plastic houseware, a bunch of people and machines are necessary to accomplish the process. But before enabling all the stages the first step is to have a budget. A budget and an idea of the houseware you actually want, which includes research about similar products and your market, are essential to creating a successful product.

Then, you have to contact a company that is able to carry out with your project, if possible from the product design to the distribution, through manufacturing and packaging. Although it may be difficult to find a suitable business, it’s not impossible. If you have a project in mind and need assistance to bring it alive, don’t hesitate to contact us.

Plastic design and manufacturing is a process that includes different stages and involves many professionals, designers, engineers, and technicians, as well as laborers and more personnel. Every step is important and defining to achieve the product you’re looking for.

Interested in knowing how can you achieve a good design for a plastic product?

Find more information by clicking and reading our post about plastic product design.

As we’ve talked about this process on previous posts, we’re gonna focus now on a specialized aspect named Design for Manufacturing (DFM) and highlight some of its features as well as why is it a good option for plastic production.

Plastic Design for Manufacturing (DFM)

Design for Manufacturing (DFM) is a process in which parts, components, or even the whole products are designed in order to ease the manufacturing with the objective of making a better product at a lower cost [5].

In the case of the plastic industry, DFM combines science, art skills and technologies that meet customer quality and cost expectations, in this way, higher levels of customer satisfaction, lower production costs and greater profits are expected [6].

To be successful, DFM brings together the molder, the Original Equipment Manufacturer (OEM), and the customer. They will work with different technologies and plastic product design, which involves deciding on the most suitable materials to deliver the quality demanded by your clients and prospects.

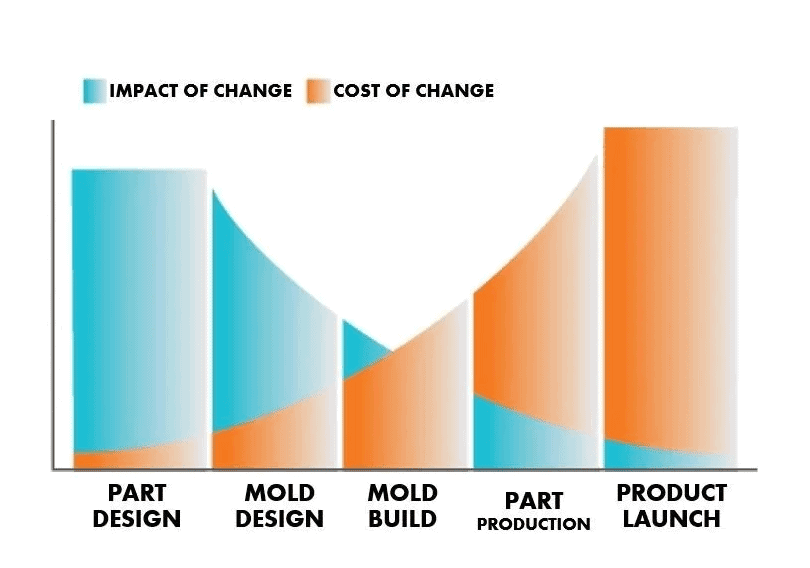

The main reason for applying DFM to manufacturing a plastic product is that up to 70% of the manufacturing costs are determined by design choices [6].

DFM is also key to another common client demand: lowering the costs of manufacturing and assembly. To accomplish this, there are a series of things to be done, like designing to reduce the total number of parts, limiting the number of machine operations needed, or designing parts to be multi-functional.

Source: East West Manufacturing.

Once the product is designed, it’ll go to manufacturing, and here when using DFM guidelines, the cost of components, the assembly, and the supporting production of the injection molder are expected to be lowered.

A molder that runs according to DFM principles will work better with complex plastic injection molded parts. It also lowers production costs, increases quality, and reduces production time. So the benefits are great when producing massively, great news for plastic houseware sellers or toy manufacturers and retailers.

If you want to learn about the manufacturing process and more of its details,

click and read our article about plastic injection molding.

Let’s imagine that you want to sell flatware and drinkware suitable and attractive for kids. Plastic design and manufacturing, could be under the DFM model, come very handy for this, as we’ll see next.

A few examples of plastic design and manufacturing on houseware

A lot of plastic manufacturers around the world know that houseware is a very profitable market for them. Alibaba, China Plastic CNB, or American Plastics Inc. are just a few examples of enormous companies that get their plastic houseware products manufactured and sold all over the world.

But what about if you want customized products, what if you want to deal directly with a manufacturer that will guide you through all the process, which, of course, includes plastic design and manufacturing.

In that case, you can contact a number of companies available to assist you. In Martin’s, we manufacture a great variety of plates, liquid containers, from mugs to thermos, air fresheners, lunch boxes, and different containers.

We’ve worked with global companies such as Danone and its brand Bonafont, which markets bottled water; Anheuser-Busch Inbev that sells beer globally; Whirley Drinkworks, a US leader in production and distribution of drinkware; Newell Rubbermaid Global, leader in many houseware goods, and Andatti, the coffee division of OXXO, the Mexican chain of convenience stores, which is the largest one in Latin America.

But it’s important to say that we can carry out any project that involves producing the best quality plastic houseware items. What about colorful lunch boxes that will cheer up schoolchildren and remember how much their parents care about them? Or some fancy pet food bowls that will make the animal lovers but them for their lovely companions?

Cooking utensils and food storage containers are a must for every home. In Martin’s, we are able to bring to real life that item you’re thinking of with plastic design and manufacturing, all the process under the most strict security measures and with top-notch technology and great quality materials.

You can imagine expanding to plastic houseware since it comprises the most diverse items that every person in the world needs to have a good life. But let’s not forget that no product is sold by itself.

As a retailer, you need to picture clearly your market and do some research. If you want to sell plastic houseware, know your competition, your potential clients, and their needs and tastes. Introduce different strategies, such as retail marketing, so you can ensure and boost your sales.

Do you have an idea in mind after reading this?

Give us a call or send us an email so we can help you.

COVID-19 and plastic design and manufacturing in houseware

As you may imagine, plastic houseware items are amongst the products that have increased their demand during the COVID-19 pandemic as millions of people around the world went under lockdowns to prevent contagion, however, medical supplies and personal protective equipment (PPE) have positioned as the most demanded products [7].

Are you interested in how the plastics field has been affected by the COVID-19 pandemic? Find out clicking here and reading our post about it.

Anyway, the future of houseware is still kind of uncertain concerning changes, modifications or adaptations to the plastic design and manufacturing within the new normality after the COVID-19 pandemic. Reports and projections, such as the Global Plastic Houseware Product Market Report forecast the global industry until 2026 [8].

Despite this uncertainty, it’s not a dreary scenario, because based on key market players, company profiles, sales, revenues, and the volume of demand and supply during 2015-2019, the forecast is optimistic: the market is expected to generate profitable prospects for producers and sellers post COVID-19 crisis [8].

So, don’t be overwhelmed by these global difficult times, people are going to keep requiring all types of houseware, even more, as hygiene and health measures are being strengthened and recommended, so it comes with no surprise that there’s a rise in products such as hand sanitizers, which come in plastic bottles, and plastic packaging for food delivery, as well as face shields, even Amazon is fabricating the latter [9].

Just look around your home and see how many items are made of plastic. That much is the number of opportunities waiting for you to be a successful plastic houseware retailer, and in Martin’s, we’re ready to assist you. Contact us and let’s make those products you’re thinking of a reality within the market!

REFERENCES:

[1] Plastics Europe. Plastics – the Facts 2018. Plastics Europe, 2018. Accessed 8 Jun. 2020.

[2] Huabiao Plastic. China's plastic products industry is promising. Huabiao Plastic Technology, 2018. Accessed 8 Jun. 2020.

[3] Plastics. Jobs in U.S. Plastics Industry Increase According to 2018 Size and Impact Report. Plastics Industry Association, 2019. Accessed 8 Jun. 2020.

[4] El Grande. Mexico’s Growing Plastic Industry: A World Market In Demand. El Grande, n.d. Accessed 8 Jun. 2020.

[5] East West. What is Design for Manufacturing or DFM? East West Manufacturing, 2020. Accessed 8 Jun. 2020.

[6] Plastic Components. Guide to Design for Manufacturing in Plastic Injection Molding. Plastic Components Inc., n.d. Accessed 8 Jun. 2020.

[7] Martin’s Plastics. Plastics manufacturing companies during COVID-19 l Martin's Plastics. Martin’s Plastics, 2020. Accessed 8 Jun. 2020.

[8] David. Global Houseware Product Market with (Covid-19) Impact Analysis: Worldwide Key Industry Segments & Forecast, 2020-2026. 3W Market News Reports, 2020. Accessed 8 Jun. 2020.

[9] BBC News. Amazon to make face shields and sell at cost. BBC, 2020. Accessed 16 Jun. 2020.

Leave a Reply