Plastics, all types of them, have permeated modern societies since the past half-century approximately, taking up a high position within the economy due to their indisputable functional characteristics and their low cost.

In the last decades, world plastic consumption has increased by 20 times and it is expected to double in the next two decades [1].

All this plastic use doesn’t come with any side effects. So, what has the plastic industry been doing to offer solutions for this growing issue? Let’s find about it and know the role that recycled plastic products play in this objective.

Plastics and their impact on the environment

As useful as they are, plastics also have their drawbacks. Especially when they’re mismanaged and end up in oceans, rivers, and other water basins. So it is a problem that affects all types of ecosystems and every corner of the world.

It is estimated that between 1950 and 2015, 6.3 million tonnes of plastics waste were generated [2].

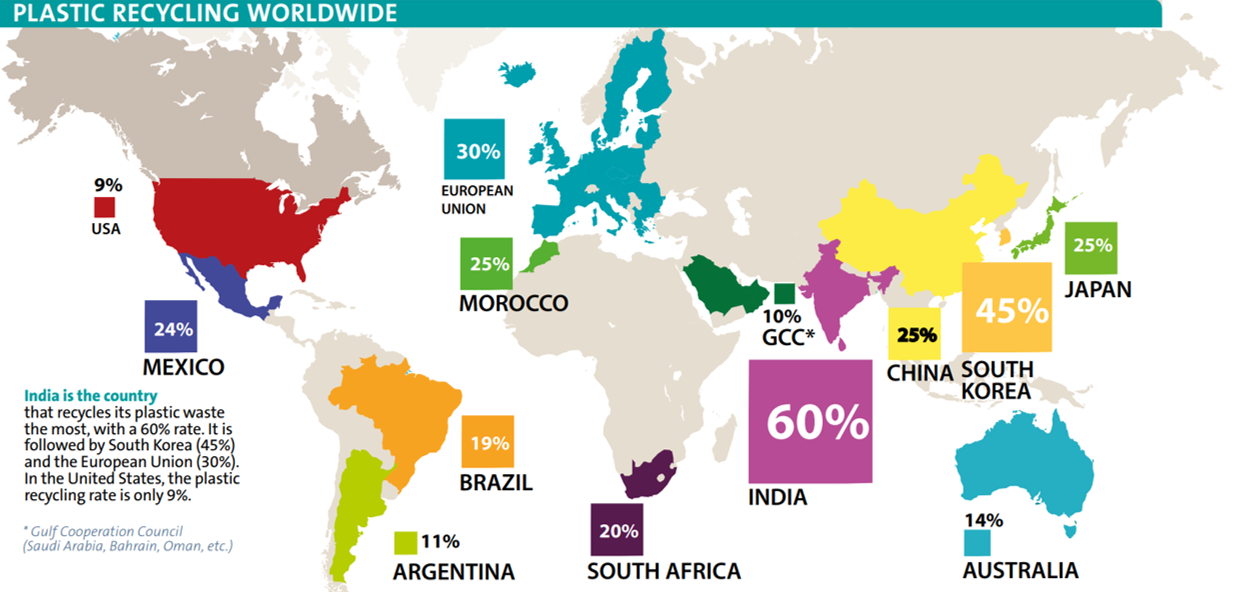

According to an OECD report, of the plastics waste produced in the last six decades, only about 9% of it was recycled and 12% was incinerated, so that leaves around 80% of plastics waste accumulating in landfills or natural environments [2]. With these numbers, it is safe to say that recycled plastic products are still kind of a rarity.

Water bodies aren’t yet shielded from pollution, a situation highly related to the economy. Water pollution particularly affects middle and low-income countries where mismanagement is a regular practice.

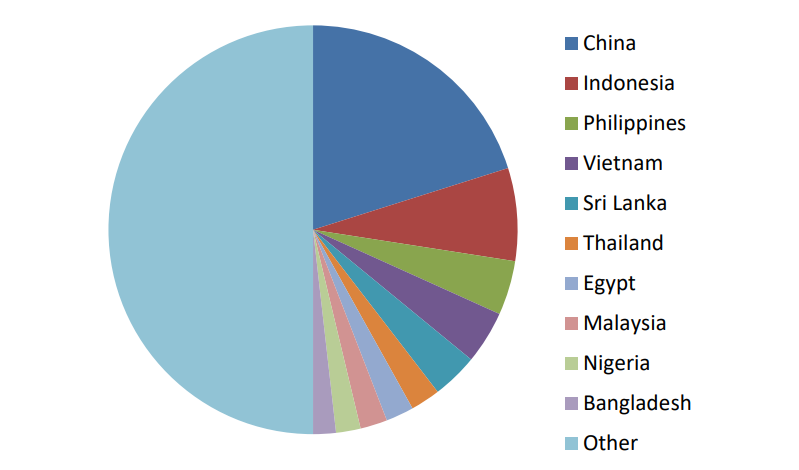

Unfortunately, plastic waste can end up in oceans. Ten rivers in Asia and Africa are responsible for a quarter of marine plastic litter and it is expected that by 2025 for every 3 tonnes of fish in the ocean there will be 1 tonne of plastic [3].

Sure, it seems like an enormously dreary outlook, but not everything is beyond repair. So, next, you’ll learn about some of the proposals and measures that the plastic industry has been made or implemented to keep the environmental impact at a minimum.

Plastic industry solutions

So, with all these issues surrounding the production, use, and disposal of plastics, the plastic industry hasn’t just sat there and seen these problems happening. The challenge is huge and in the last two decades, we’ve seen big economies and multinational companies pushing for more green practices.

To address the plastic issue, several plans for long-term solutions have been traced, and a bunch of actions, regarding short-term solutions, have been taken. Beyond recycled plastic products, which are one of the most recognized measures, here are three core ideas to prevent and reduce the environmental side effects of plastics [2]:

• Changes in production: plastic product design is one of the essentials in plastic manufacturing, so the use of biodegradable and greener plastics in production is one of the ways to decrease the generation of plastics waste. Modifications to design practices, like lighter products, could also come handy in the reduction of waste.

• Improvement of waste management systems: more sophisticated and higher waste collection, as well as a rise in recycling processes, would lead to having better control over plastics waste, preventing problems in natural environments, and causing a big reduction of mismanagement.

• Remediation actions: this has come not as a prevention practice, but as a way to help with the removal of plastics already in natural environments, like beach clean-ups and top-notch technology to collect plastics waste from oceans.

It is clear that every practice that fits these three points comes with risks and costs, and it’s ideal to think that every plastic company in the world will adopt every green measure. It’s a matter of capacities and cost-benefit, and, of course, nations politics.

In Martin’s, we’ve come up with staggering solutions. Our cooling circuits are designed to prevent water loss by leaking or evaporation, in that way we lessen the energy consumption too. We also use recycled plastic from reliable suppliers, so we guarantee its traceability and full provision.

Regarding modifications in production, we’re proud to have adopted poliagave, an FDA-approved biocomposite material that integrates agave fibers and makes the product not only biodegradable but easier to recycle. If you have a big scale project that you think may benefit from this material, contact us and we’ll be happy to answer your questions and guide you through it.

Want to learn more about the defies that the plastic industry faces?

Don’t miss our article about challenges and solutions for plastic manufacturers.

Recycled plastic products within the circular economy

Recycled plastic products are part of this large campaign to address the impact of plastics. They are crucial too for what has been called “circular economy” and they are considered too under the New Plastics Economy plan, fueled by the Ellen MacArthur Foundation and the UN Environmental Programme.

The circular economy involves a more responsible production and consumption of products, it follows an improvement of design to achieve resource efficiency and applies the 3-R rule: reduce, reuse, recycle [3].

This concept is the basis of the New Plastics Economy plan that intends plastics to never become waste, by re-entering the economy. To do so, it focuses on creating an efficient after-use plastics economy, which includes reducing plastics leakage into the environment, especially oceans, and eliminating fossil feedstocks [1].

As of 2020, 53% of plastic packaging in Europe could be recycled benefiting not only the environment but the economy [1].

As a long-term action plan, it is one ambitious, it was launched in 2018, and it has been signed on by hundreds of companies, including huge ones like Nestle, Pepsico, Unilever, Walmart, and Target.

Each company has adopted different levels of commitment, but one of the shared goals is to have, by 2025, all their plastic packaging reusable, recyclable, or compostable [4].

Some heavy plastic use companies are still missing, such as Amazon, Costco, Procter & Gamble, or major toy manufacturers, but optimistically, more companies will turn to green practices and achieve some of the goals before described.

But, as hard as it gets, not everything’s lost. There is so much the plastic industry, the world nations, and the society, altogether, can do to protect the environment and make Earth a healthier, cleaner place to live without dropping the use of crucial materials.

Day by day, in Martin’s we’re committed to reaching excellence by offering the best products with the best technologies and through green practices, such as wind power, which fuels all our plants for their electricity consumption. Feel free to contact us if you want to discuss a big plastic product project.

Recycled plastic products: a growing solution

Each one of the three Rs proposed deserves special attention as they, together –reduce, reuse, recycle–, aim to make the plastic industry more sustainable and eco-friendly. Recycled plastic products are one of many solutions that the industry has effectively implemented.

Before we present to you some ideas and practices concerned with recycling, let’s remember that customers have been following ecological measures, by conscious or unconsciously adopting the reducing and reusing directives, such as reused plastic bags. Also, durable plastic objects help to reduce single-use plastic waste.

Plastic houseware goes through a careful designing step in their manufacturing process. Fact or myth? Click here to know the answer.

The manufacturing industry has made different efforts to fulfill a less detrimental impact on the environment. Recycled plastic products are a great way to ameliorate this condition.

The recycling industry is nowadays very complex and diversified. As for plastic recycling, typically after the plastic objects are collected, the recycling plant will separate the plastic into different polymer types.

Once the polymers are divided, they are cleaned up, to remove other materials like paper, then they are shredded and melted back into polymer pellets. These pellets ultimately are the basis for our new recycled plastic product [5].

A ton of recycled plastic means 16 barrels of oil less and 60% less energy required to produce, compared to virgin plastic [6].

In the end, along with other recovery processes, recycling helps to alleviate the environmental impact, by expelling fewer greenhouse gas emissions, or reducing the amount of plastic in landfills and oceans. It even helps to save costs for various industries.

Recycled plastic products in companies: what can recycled plastic become

Some important companies have adopted recycling as one of their main politics. Their production includes clothing, footwear, houseware, or even promotional products. Here are two examples that stand out for their commitment.

Everlane is one company that has promised to go greener and each action speaks for them. In 2018, they started to use alternatives to polyester in production, and in 2019, they reduced single-use plastic in offices and stores and began to ship orders in 100% post-consumer recycled poly bags [7].

As for recycled plastic products, their new collection, ReNew, offers jackets and sweaters made with recycled plastic bottles. And by 2021, Everlane has committed to eliminating all virgin plastic from its supply chain [7].

The American company Patagonia claims to be the first outdoor clothing manufacturer that turned trash into fleece: since 1993, they’ve been collecting plastic soda bottles to make recycled polyester [7].

They even use worn-out apparel to produce this material so they can offer a wide range of garments, from backpacks to winter gear to T-shirts, as recycled plastic products. Now, this is a way to make the most of their production!

In Martin’s, our commitment with a better and healthier world has led us to search for green practices. For instance, we work with recycled materials, like polyethylene, polypropylene, and styrenics.

Some of our own plastic scrap gets recycled with our suppliers who have the equipment to sort, wash and dry, shred, melt and extrude the plastics to create new pellets which are used in our products like toys and games, it’s a way to contribute to lessening the environmental impact.

The cases appointed are maybe sophisticated examples of what powerful companies can be doing with recycling trends. But recycled plastic products are increasing and come in many shapes and possibilities. Let’s check out what the everyday plastics you use can become.

• Plastic containers and bottles used for milk, shampoo, detergent or cleaners can make new bottles and containers, but also plastic lumber, picnic tables, playground equipment, trash bins, or even lawn furniture [8].

• Plastic bags and wraps make excellent material to produce awesome recycled plastic products like park benches, backyard decks, and fences. Besides, these items are recycled into new plastic bags over and over again [8].

• Plastic bottles for different beverages, as you’ve read, can be transformed into clothing and garment, nearly 30% of plastic bottles in the US are recycled [8].

• Bottle caps have been recycled to produce car batteries, garden rakes, containers, ropes, or brooms.

Are you interested in the plastic containers market?

Learn about how they’re made and more useful information by clicking here.

Finally, all this variety of recycled plastic products is not only a big effort, but it’s also evidence of their success between the customers, something that has turned recycling into a profitable business.

As more people grow concerned about the environment, recycled plastic products and other green practices in the industries have attracted more attention. Retail marketing strategies aren’t oblivious to that: that’s why sometimes the emphasis of a product is its eco-friendly properties.

In Martin’s, the relationship with our potential customers and our clients is one of our priorities to offer the best service. Give us a call or send an email and we’ll assist you with any large plastic project you may have by discussing our green options.

Towards plastics sustainability

After all this, we would want to give our closing comments on this important topic: sustainability. For a product or material to be characterized as sustainable, it is necessary that they prove to have a positive or least damaging impact environmentally, economically, and socially [9].

These aspects are known as the Three Pillars of Sustainability and plastic pollution solutions have been contributing to these three very essential pillars. Just by being recyclable, plastics fulfill the environmental aspect through their energy-saving potential [9].

Only 4% of global oil production is used to produce plastics and much less energy is required compared to other materials [9].

Many industries benefit from plastics, like packaging, healthcare, construction, and transports, because of its low cost and high functionality. Now, they have been introducing recycled plastics in order to be more ecologically responsible and to reduce energy use.

As for the economical sustainability, the plastic industry holds a major contribution around the world, as it is a powerful manufacturing sector, essential for the world economies in macro and micro levels [9].

As for the social pillar, the plastic industry is sustainable because it offers a wide range of job possibilities to thousands of people around the world. Besides, plastics play a huge part in people’s safety, ranging from airbags to protective equipment to edible packaging.

In conclusion, with a green future in mind, the plastic industry has offered an array of creative and possible answers to lessen the environmental damage and reach a total sustainable status to contribute to making our planet safer, cleaner, and healthier.

In Martin’s, we’re aware of this issue and we’re working to adopt more eco-friendly guidelines. We can work with recycled plastic, from 5% up to 100% of the product, if you need it. Get in touch and learn more about our circular economy solutions based on recycled plastic products.

REFERENCES:

[1] World Economic Forum, Ellen MacArthur Foundation and McKinsey & Company. The New Plastics Economy: Rethinking the Future of Plastics. Ellen MacArthur Foundation, 2016. Accessed 7 August 2020.

[2] OECD. Improving Plastics Management: Trends, policy responses, and the role of international co-operation and trade. Organisation for Economic Co-operation and Development (OECD), 2018. Accessed 7 August 2020.

[3] Gemma James. The Plastics Landscape: The Challenges and Possible Solutions. Principles for Responsible Investment (PRI), n. d. Accessed 6 August 2020.

[4] Deborah Kapiloff. The New Plastics Economy: A Bold New Plan to Combat Plastic Pollution. Institute for Local Self-Reliance (ILSR), 2019. Accessed 7 August 2020.

[5] BPF. Plastic Recycling. British Plastics Federation (BPF), n. d. Accessed 7 August 2020

[6] Emma Roche. Beyond Plastic: 10 Eco Products Made From Recycled Plastic. One Green Planet, 2013. Accessed 7 August 2020.

[7] Mara Leighton. 14 companies that are capitalizing on the unpopularity of plastics. Business Insider, 2019. Accessed 7 August 2020.

[8] Recycle Your Plastics. What Plastics Can Become. Recycle Your Plastics, n. d. Accessed 7 Augusto 2020.

[9] BPF. Plastics: Recycling and Sustainability. British Plastics Federation (BPF), n. d. Accessed 7 August 2020.

Leave a Reply