Where to manufacture is a big decision to make for any company that wishes to fabricate any product. This process is essential and any company would consider costs, transportations, taxes, quality, and efficiency. One of the biggest markets in the world, the United States of America, has a lot of merchandise produced abroad.

Manufacturing in Mexico has become one of the best options for businesses that are in search of cutting costs in production to get their articles competitively in the global market, and especially in North America.

In this post, we’re going to talk about the advantages Mexico offers when it comes to manufacturing, where do you need to look up if you’re interested, the top manufacturing industries in Mexico, and finally, in a few words, what are the benefits specifically for plastics manufacturing.

Why manufacture in Mexico?

If you’re a U.S.-based corporation, one of the first reasons to choose Mexico as your manufacturing option is proximity, that’s the main reason why American companies have been manufacturing their products in Mexico for 50 years [1].

Nevertheless, there is a number of reasons to manufacture in this Latin American country, no matter if your company is based outside the States. Whether you’re looking for electronics manufacturing or toy manufacturers, it doesn’t matter which is your branch in business, Mexican manufacturing industries are great options for you. Here are some of the benefits of manufacturing in Mexico [1] [2].

- Competitive costs

Quality is a fundamental trait that companies search for, when this combines with cost savings it’s like hitting the jackpot. Mexico is one of these places: it has low costs and excellent quality. When compared to the United States, and many other developed countries, Mexico’s workforce turns out to be around seventy percent less expensive.

This low cost in production explains largely the success of manufacturing in Mexico. In addition, there are Mexican programs and decrees to guarantee foreign investment. One of these programs, we’ll talk about it later, is the IMMEX.

- Free trade agreements

Mexican governments have been essential to manufacturing success. One of the most impressive facts in this field is that Mexico has the most free-trade agreements in the world.

Texto destacado: NAFTA, and now the USMCA, has been crucial to strengthen the North America circuit. And with the new CPTPP, manufacturers and suppliers can enjoy tariff-free access to 11 countries throughout the Asia-Pacific (Canada, Australia, Brunei, Chile, Japan, Malaysia, New Zealand, Peru, Singapore, Vietnam and, of course, Mexico).

These are just two examples of approximately other forty-three trade agreements this country has, which enable shelter manufacturing there, as well as allows raw materials and components imports, duty and tax-free.

- The infrastructure

Mexico has been for years a country open to foreign investment, this financing, along with governmental funding, has provided modern facilities, roads, power, and water to the country that impact directly in good conditions for manufacturers. An established infrastructure permits to operate without disruption and that’s why many foreign companies are content to manufacture in Mexico.

- The labor force

Another reason why Mexico has grown in manufacturing is its manpower. Mexican workforce is highly educated in general and has nothing to ask to virtually any developed country in the world.

Mexico also offers a pool of talented and high-skilled operational workers and professional managers who help companies expand well beyond their initial expectations.

Texto destacado: Additionally, the workweek in Mexico is 48-hour long (compared to the 40-hour in the States), and the wages are considerably less than in the States and 14.6% less than China.

- Prominent Industries

Manufacturing in Mexico began more than five decades ago, the low-cost labor rates were a good catch for foreign companies. This fact helped consolidate diverse industries in Mexico. Nowadays, major Mexican industries have attracted global manufacturing companies like Volkswagen, GM, Bombardier, Bose, and many more.

Manufacturing in Mexico has grown across all industries, the aerospace, medical, and electronics device are some of the most benefited industries. Recently, however, a boom in the automotive industry is visible: Nissan, BMW, Audi, Honda, Mazda, Ford, Toyota, and Daimler have assembly plants in Mexico and over 500 new automotive suppliers from around the world have arrived in the country in the past decade.

Of course, there are more industries that have been successful in the country, among them we find the plastics manufacturing industry. In 2016, Mexico was the 10th largest plastic producer all over the world and had a market value around $30 billion.

There are Mexican cities that clearly illustrate all of this manufacturing boom, for example, Tijuana, the most visited border city in the world, has become a manufacturing powerhouse for global companies related to major Mexican industries such as automotive, aerospace and defense, electronics and medical device.

So, these are the main reasons why Mexico is a great option for manufacturing, especially for the Americas and, to a lesser extent, for Europe. Now, to exemplify some of the government measures to secure competitive cost, we’re presenting you one of the most successful programs related to this success in manufacturing.

The IMMEX Program

As manufacturing in Mexico has grown a lot in the last decades, partly due to the economy’s growing globalization and the introduction of NAFTA and more free trade agreements, the country’s government has developed programs that attract foreign companies, one of them is the IMMEX maquiladora program.

This program is designed for foreign manufacturers that decide to invest in Mexico. It allows raw materials and components imports, tax and duty-free, into Mexico, under the condition that the total of the finished products will be exported out of Mexico within a government-mandated timeframe [3].

The main goal of the IMMEX is to enable foreign companies to manufacture in a competitive environment so it creates jobs in Mexico, helping to strengthen the Mexican economy. It also aims to modernize the manufacturing infrastructure in Mexico by importing specialized and innovative technologies and knowledge [3].

To bring this section to an end, let’s not forget that for the U.S. companies, proximity will always be one of the best advantages, and for other companies around the world, the fact that Mexico is the U.S. neighbor and is also close to Canada makes things easier if they’re willing to expand to North America.

Location factors are relevant to manufacturers planning for transportation, logistics and time-in-transit costs to get their product to market. In addition, Canadian and American executives and managers can visit more regularly their Mexico operations and manufacturing facilities. Finally, for South American companies, it’s no secret that Mexico works as a bridge in the region, connecting North, Central, South America, and the Caribbean.

Where to manufacture in Mexico?

Products manufactured in Mexico go far beyond simple assembly, in the present, many companies design, develop and manufacture really complex products in a variety of industries. If you have decided to do your manufacturing in Mexico, after evaluating the costs, one big step to take is to identify the region that suits the best to your company.

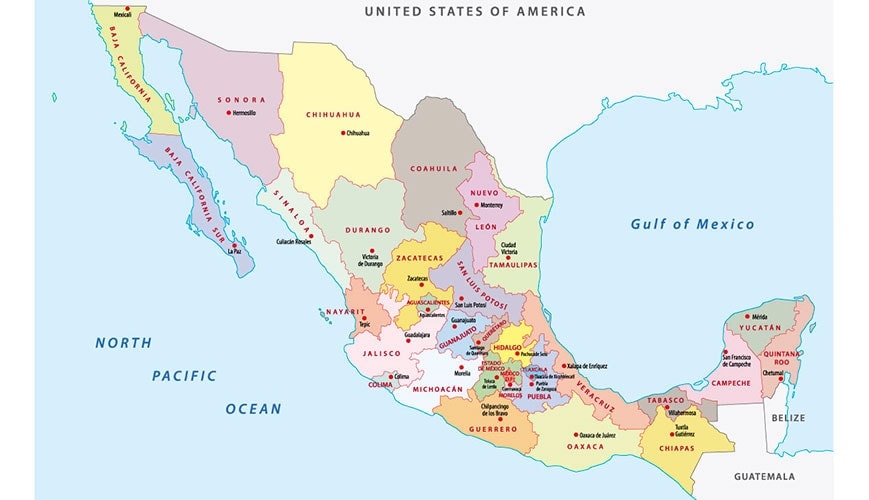

Since the 70’s decade, foreign companies have installed manufacturing facilities in Mexico to export most of their production, these manufacturers are called maquiladoras. Six Mexican states bordering the U.S., Baja California, Sonora, Chihuahua, Coahuila, Nuevo León, and Tamaulipas, comprise around 56% of the maquiladoras. The rest are located throughout the other 26 Mexican states [4].

Texto destacado: Choosing a location not only requires deciding on a region or a city but selecting a manufacturing site. There are three general kinds of locations: a single building, a site within an industrial park, or a manufacturing community, which is an industrial park with embedded manufacturing support services [4].

The next thing you should look for are the infrastructure conditions, which major highways, land ports of entry, seaports, airports are close to the facility. The same with the proximity to the supply chain. Making a decision depends, of course, a lot of the goals the company has.

Now, there are two major manufacturing regions in Mexico, the Border Region and Central Mexico (with the “Bajío” Region included).

Manufacturing in Mexican territory along the U. S. border makes easier the delivery to American and Canadian customers and distribution centers. Some of the industries that have grown a lot in this region are related to aerospace, medical devices, electronics and consumer products sectors [1].

Industrialized border cities (west to east) that are very popular are: Tijuana (Baja California), Mexicali (Baja California), Nogales (Sonora), Ciudad Juárez (Chihuahua), Nuevo Laredo (Tamaulipas), Reynosa (Tamaulipas), and Matamoros (Tamaulipas). These are not the same as the most popular industrialized cities in the interior of border states, such as Hermosillo (Sonora), Guaymas/Empalme (Sonora), Chihuahua (Chihuahua), Monterrey (Nuevo León), Saltillo (Coahuila), and Torreón (Coahuila).

The central region of Mexico has experienced an important market growth in the aerospace and automotive industries over the past years. Automotive companies have invested billions of dollars to establish their manufacturers in Mexico, so a lot of suppliers have migrated to these regions to finish the supply chain. Besides, in this region is located Querétaro, which is the Mexican state that leads the plastic production in the country.

This region consists of the following industrialized states: Mexico City, Guanajuato, Jalisco, Querétaro, Puebla, Estado de México, San Luis Potosí, and Aguascalientes.

Texto destacado: If you’re interested in manufacturing in Mexico, a good option is shelter companies, which follow a process where foreign companies are allowed to set up a maquiladora without going through the same paperwork of opening a Mexican company.

It’s a form of outsourcing, letting shelter services handle the finding of your location, the acquisition of equipment, they also deal with getting all the permits and paperwork. Some examples of these companies that work in Mexico are Prince Manufacturing, Tetakawi, Tecma, NAPS, and Co-Production International.

Top Manufacturing Industries in Mexico

Manufacturing in Mexico has flourished because of the cooperation between many actors, such as the Mexican government, private sector financing, and, of course, all the investment from abroad. Mexico has become a very attractive manufacturing place too due to its access to the global market and its local suppliers.

Products are usually assembled and finished in Mexico and from there, they’re distributed around the world. Assembly employees and engineers are equally efficient and that constitutes a major cause for success in many industry sectors. Amongst all this diversity, the top 5 manufacturing industries are [6]:

1. Aerospace

- Where in Mexico? Querétaro, Sonora, Chihuahua, Nuevo León, and California.

- Which foreign companies? Bombardier, GE, IQ, Safran, Airbus, Delta, Eurocopter, Aernnova, Meggit, ITR, Cormer, Regent, and Liberty Spring are just a bunch of examples among 300 aerospace manufacturing companies.

- How much? Aerospace manufacturing revenues in Mexico make almost half of the country’s foreign direct investment.

- Fun fact: In Querétaro, the state university has enabled partnerships with Bombardier in order to develop innovative ideas and enlarge the skilled labor force.

2. Automotive

- Where in Mexico? Mainly Coahuila, San Luis Potosí, Baja California, Nuevo León, Jalisco, and Guanajuato, but automotive companies are in almost all Mexican states.

- Which foreign companies? Original Equipment Manufacturers (OEM) such as BMW, Chrysler, Ford, GM, Honda, Kia, Mazda, Nissan, Toyota, and Volkswagen.

- Fun fact: The Mexican automotive industry is the 4th largest exporter of auto parts in the world, and first in auto exports to the U.S.

3. Medical devices

- Where in Mexico? Mainly Baja California, but also Chihuahua, Coahuila, Nuevo León, Jalisco, Sonora, and Tamaulipas.

- Which foreign companies? Medtronic, Tyco, GE, Becton Dickinson, Siemens and Cardinal Healthcare, 3M, Stryker Incorporated, Kimberly Clark, Boston Scientific, and Johnson & Johnson are a few examples among almost 650 companies.

- How much? Exports have reached about $8 billion USD.

- Fun fact: The U.S. consumes around 90% of the medical devices produced in Mexico. Other countries investing in medical device manufacturing in Mexico are Italy, Germany, Spain, the Netherlands, and Japan.

4. Electronics

- Where in Mexico? Baja California, Sonora, Chihuahua, Jalisco, and Aguascalientes specialize in hi-tech, IT, and electronic assembly parts, while Coahuila, Mexico City, Nuevo León, Querétaro, and Tamaulipas concentrate on manufacturing parts for computers, home appliances, and consumer goods. Both regions work with automotive and telecommunications components.

- Which foreign companies? Plexus, IMI, IKOR, Flex Ltd., V-TEK, InterLatin, Sanmina, QSS, JABIL, Molex, OMP, Mechtron, and Talos, mainly with facilities in Guadalajara, Jalisco.

- How much? Annually, this industry exports about $150 billion USD in products.

- Fun fact: Guadalajara is home to 12 OEM and more than 300 specialized suppliers.

5. Appliance Manufacturing and Furniture Manufacturing

- Where in Mexico? Querétaro (Querétaro), Tecate (Baja California), Guadalajara (Jalisco), and Saltillo (Coahuila) are the cities where most of this industry is based.

- Which foreign companies? Sony, Whirlpool, GE, Zuo, Amana, Danby, Ethan Allen, EMZ, Siemens, and Diehl Controls, among others.

- Fun fact: Mexico has become the 5th largest exporter of appliances in the world, and a major exporter within the furniture industry.

Plastics Manufacturing in Mexico

Another important sector among all the diversity of manufacturing industries in Mexico is plastics, with over 4,000 companies producing plastic products all throughout the country. In 2016, the plastics market value inside Mexico exceeded $26 billion, and the same year, out of the 1.9 million tons of plastics produces, 34% was exported [7].

Plastic manufacturing, through plastic injection molding and other processes, produces mainly packaging materials and molding structures (in order to fabricate other products, or even in plastic product design), an important commodity for suppliers. Plastic products are the principal point of meeting between suppliers and the automotive, aerospace, electronics, and appliance industries.

Of course, a diversity of other plastic products is manufactured in Mexico by foreign and national companies, such as home cleaning products, food and beverage packages, promotional products, and toys. Some transnational companies have chosen local manufacturers to fabricate their products, we, at Martin’s, are open to working with any company that needs plastic manufacturing at high quality and a competitive cost.

To sum it up, manufacturing in Mexico is one of the most profitable sectors in the country, providing a good number of services, locations, and facilities to many foreign companies. Top manufacturing industries in Mexico have benefited from programs and free trade agreements that motivate foreign investment. While companies from all around the world choose Mexico because of its competitive costs, infrastructure, and labor force, this country strengthens its economy, increases its exports and creates jobs for Mexican people. It seems like a win-win deal.

REFERENCES:

[1] https://www.co-production.net/manufacturing-in-mexico

[2] https://napsintl.com/manufacturing-in-mexico/why-manufacture-in-mexico/

[3] https://napsintl.com/manufacturing-in-mexico/the-immex-program-manufacturing-in-mexico/

[4] https://tetakawi.com/manufacturing-in-mexico/where-to-manufacture-in-mexico/

[5] https://www.eluniversal.com.mx/english/queretaro-leader-plastics-production-mexico

[6] https://insights.tetakawi.com/top-5-mexican-manufacturing-industries

[7] https://insights.tetakawi.com/mexicos-plastic-manufacturing-industry

As I web-site possessor I believe the content matter here is rattling wonderful , appreciate it for your hard work. You should keep it up forever! Good Luck.

You made a great point when you said how manufacturing your products in Mexico will not only cost less, but will also give you excellent quality. Some possible co-owners and I are looking for advice to start a business in which we will mainly need plastic injection services. I will make sure they know what you recommended, and we´ll start looking for the right company to do it.

Fantastic article post.Much thanks again. Great.